WHAT WE DO

Testing & Fault Finding

Electrical testing and fault finding for train operators

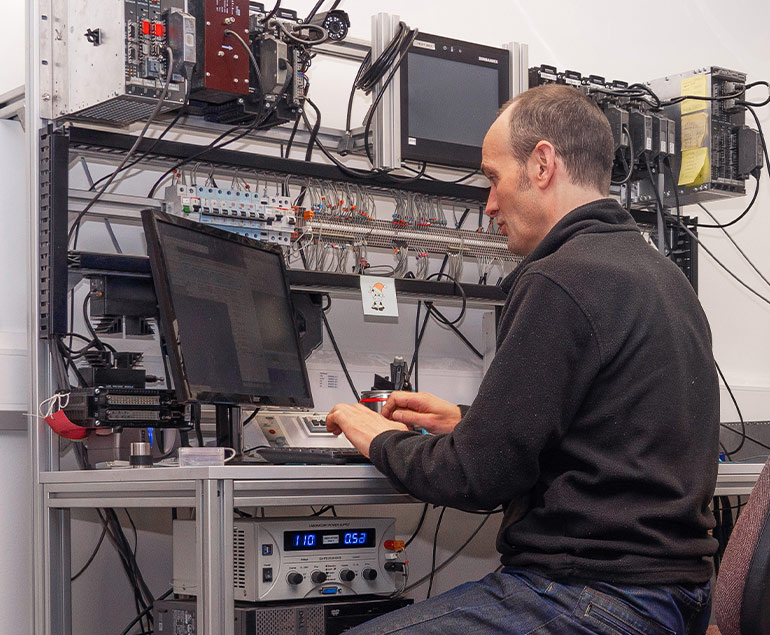

eTrac’s in-house testing service provides highly-effective fault finding and compliance assurance for train operators.

Our capability helps to ensure that faults can be reliably detected and resolved. Benefits include reduced in-service faults, saving customers significant cost and avoiding operational issues.

eTrac’s testing also overcomes the need to return modules to OEMs based overseas, thereby reducing the cost to train companies and cutting the lead time by many months.

When the vehicle computer fails it causes the train to stop and results in a long delay. Our testing and repairs have reduced the number of these occurrences for our customers.

Types of testing provided by eTrac

Our in-house test facility contains bespoke test platforms for most traction and control components.

They include environmental testing in our climate chamber, which enables us to test customers’ modules under realistic (and extreme) conditions often experienced on the train.

Where available and beneficial, we use previous diagnostic data to further our understanding of faults. This may be train data (provided by the train company), module data or statistical data from our records. eTrac has an extensive database of component faults dating back to 2009.

We test components and modules of all types and sizes.

Here are some of the main ones. Large units can be unloaded by forklift in our spacious workshop area:

Brake resistors

Auxiliary converters

Motor converters

Line converters

Associated high voltage traction boxes/equipment

Analogue IO modules

Digital IO modules

Comms module

Line interference monitors

Vehicle computers

.

.

eTrac’s approach to testing and fault finding

Our overhaul work follows a tried and tested process with all work carried out in accordance with industry standards.

01.

Pre-test

02.

During overhaul / repair

At this stage our own test data may be supplemented by diagnostic data provided by the train operator or from our own database of faults.

03.

Climate chamber

04.

Post test

For more information on our services and to see how we can help, contact us today on 01483 671544 or fill in our contact form and we'll call you back.