SOLUTIONS

Brake resistor repair and servicing

Fast, reliable brake resistor repair and servicing

eTrac provides fast, reliable brake resistor repair and servicing that reduces the time that trains need to be taken out of service.

Having worked on brake resistors since 2010, we have developed extensive expertise and can repair most mechanical, electrical or control faults.

Offering short turnaround times, we typically complete standard work within ten working days and provide a rapid response service for emergency repairs. As with all our work, we offer a one-year standard warranty with support whenever it’s required.

Our team is extremely flexible and caters for the requirements of every depot’s particular fleet. We can also provide maintenance support, working in tandem with depots’ servicing schedules and helping to detect early warning signs and avoid brake resistor failure.

Holding stock to reduce lead times

eTrac customers benefit from an extensive stock of high-value brake resistor spares that we purchase and hold within our warehouse. The components have an extremely long lead time and having these to hand avoids significant delays.

What are brake resistors and how do they work?

Brake resistors are required for trains’ dynamic braking and power stabilisation. When braking, the traction motor becomes a generator and the energy produced is chopped through the brake resistor or returned to the supply. The resistor will heat extremely quickly due to the high power from the traction converter. Forced cooling of the resistor elements is provided by a fan.

Why do brake resistors fail?

Train brake resistors fail due to various problems with the resistor elements, electrical connections or cooling fan. The faults cause the traction system to isolate and reduce the performance of the train. The braking of the coach reverts to friction braking and causes more wear of the brake pads, leading to increased maintenance.

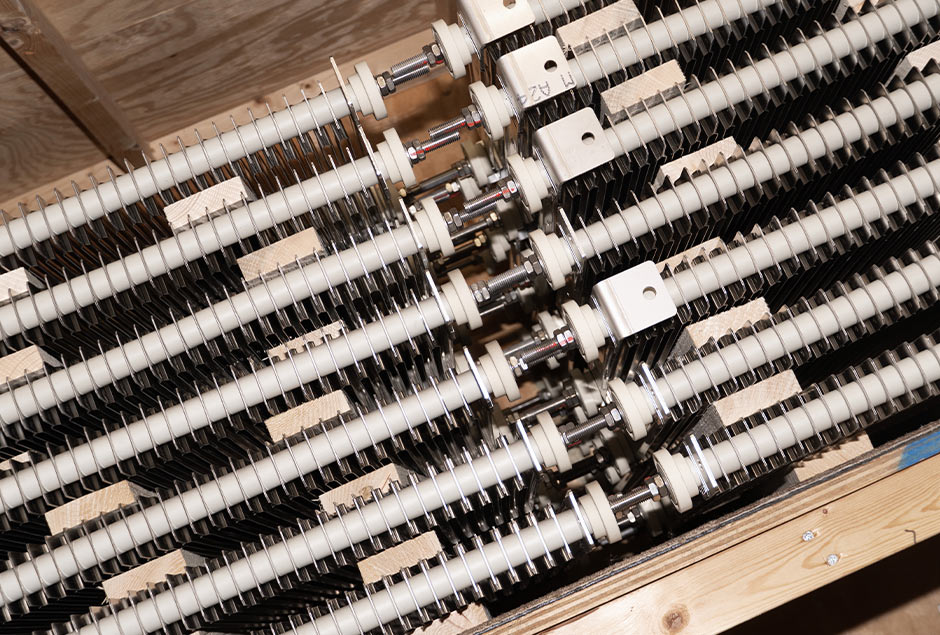

Resistor elements

These high-temperature stainless steel elements operate within a harsh environment on the exterior of the train and are prone to failures. Fractures (due to expansion and contraction) or deformation (due to overheating) cause open or short circuits. The elements are electrically insulated by ceramic insulators and these can crack, leading to a breakdown of isolation.

Cooling fan

The fan requires regular maintenance to ensure it is clean and free running. The fan can suffer from overheating or bearing failures.

Sensor PCB

To ensure the resistor is being adequately cooled, a detector circuit measures the fan rotation speed. If the fan speed falls below a predetermined level the brake resistor will be temporarily disabled. The sensor PCB is prone to failure over time and can inhibit the brake resistor function unnecessarily.

For more information on our services and to see how we can help, contact us today on 01483 671544 or fill in our contact form and we'll call you back.