SOLUTIONS

DX Unit, DI Unit and AX Unit overhaul and repair

Alstom approved repair and overhaul service

Underpinned by our extensive experience of repairing and maintaining DX, DI and AX units, our service delivers the following benefits:

- Improved reliability

- Reduced failure rates

- Technical feedback to depots and ongoing support

- Fast turnaround

- Standard one-year warranty

About DX Units, AX Units and DI Units

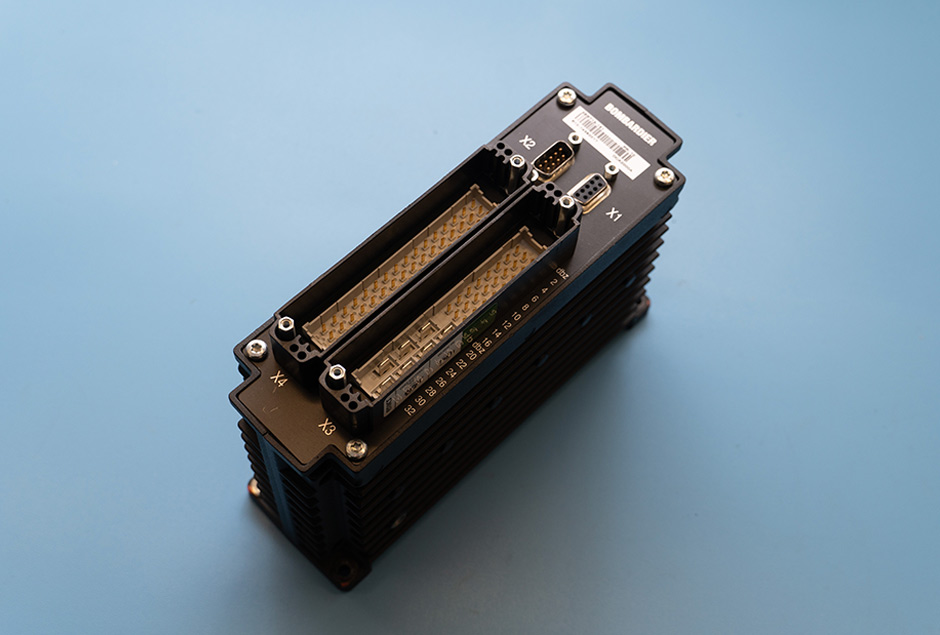

The three units function as interfaces. The DX provides a digital input and output interface, the DI is digital input only while the AX provides an analogue interface.

All are used for connection to a Multifunctional Vehicle Bus (MVB) and control by other connected equipment.

The units have a modular design comprising of two different boards, namely a CPU board and input/output board within a compact and rugged mechanical enclosure.

Components that are at risk of failure due to age include:

- Mechanical components – relays

- Wet components – electrolytic capacitors and batteries.

- Front-line components which are connected directly to extensive cabling outside the unit, including transceivers

- Critical optical components – optocouplers

Our overhaul process aims to extend the operational life of the equipment by at least ten years and reduce the number of failures within this period.

eTrac’s approach to the DX, DI and AX Unit overhaul / refresh

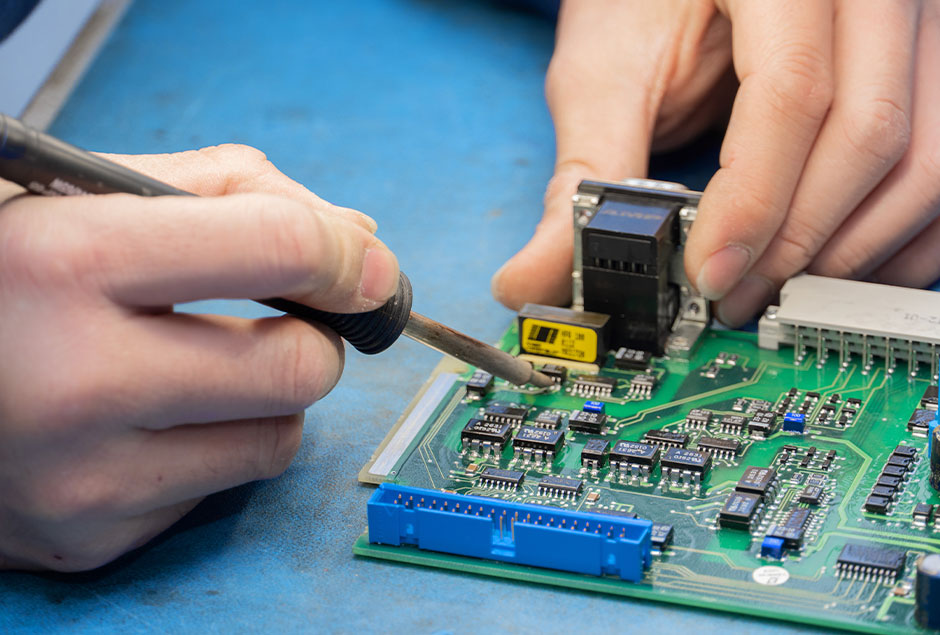

Our overhaul work follows a tried and tested process with all PCB track repairs completed to IPC7711B_7721B standards.

01.

Initial testing

02.

Repair work arising

03.

Component replacement and additional work

The unit is disassembled and both circuit boards disconnected and removed. At-risk components and any needing repair are replaced.

04.

Inspection and remedial work

05.

Reassembly and functional testing

Upon reassembly, functional testing is carried out in accordance with existing agreed test procedures. The unit is powered up and MVB functionality verified using a test bench to simulate interfaces with train-borne equipment. Testing verifies the correct function of all inputs and outputs.

06.

Identification

07.

Report

For more information on our services and to see how we can help, contact us today on 01483 671544 or fill in our contact form and we'll call you back.