SOLUTIONS

Electrostar – MITRAC Drive Control Unit (DCU) repair and overhaul

Alstom approved repair and overhaul service

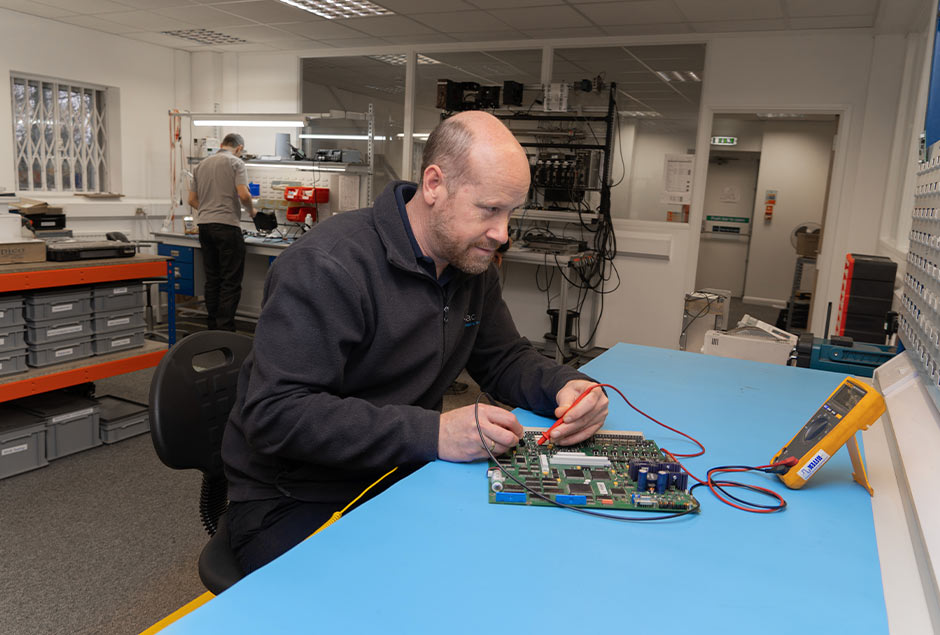

To keep MITRAC DCUs running and extend their operational life, eTrac provides a repair and overhaul service that is approved by Alstom.

Our overhaul process, which replaces all components that are prone to age-related failure, was devised based on 15 years’ experience of DCU fault-finding and testing following service failure.

Any pre-existing defects can be identified and repaired using our fault-finding service. In addition to our own testing, we also draw on train diagnostics and our own extensive repair records.

The benefits of eTrac’s overhaul and repair service include:

- Improved reliability

- Reduced failure rates

- Technical feedback to depots and ongoing support

- Fast turnaround

- Standard one-year warranty

MITRAC DCU components

The DCU has a modular design comprising a computer board, expansion board and fibre optic board. Connected to the traction control Multifunctional Vehicle Bus (MVB), it allows integrated control as part of a complete traction system.

Various analogue and digital connections are provided for interface with the converter equipment and safety-critical control connections. (See our DX, AX and DI solutions)

Components that are at risk of failure due to age include capacitors, varistors, optocouplers, optical transmitters and optical receivers.

Our overhaul service replaces all these components on a like-for-like basis. Wherever possible we use OEM components. Where this isn’t possible we will use authorised alternatives.

Our overhaul service replaces all MITRAC DCU components that are at risk of failure.

eTrac’s approach to Drive Control Unit overhaul

Our overhaul work follows a tried and tested process with all work carried out in accordance with industry standards:

01.

Visual check

02.

Initial testing

03.

Repair work arising

Any faults identified in stage 2 testing that are unlikely to be resolved by the component refresh are raised and arrangements made for repair, subject to customer approval.

04.

Component replacement

05.

Additional work

06.

Inspection and remedial work

The DCU boards are inspected prior to assembly and further checks.

07.

Reassembly and post-assembly test

08.

Functional test

09.

Identification

A label showing full details of the refresh is applied to the top cover plate.

10.

Report

A comprehensive repair report is compiled for the client.

For more information on our services and to see how we can help, contact us today on 01483 671544 or fill in our contact form and we'll call you back.